Subtotal: $26.866

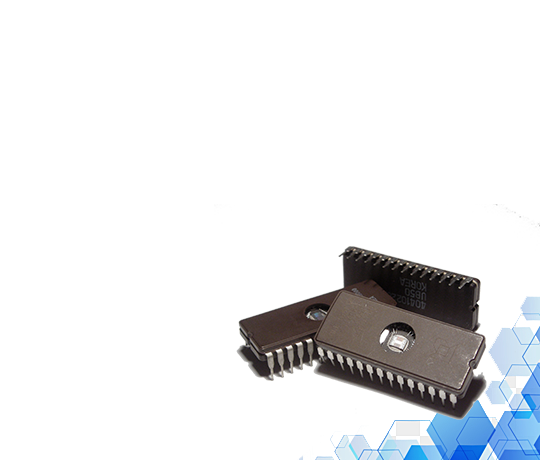

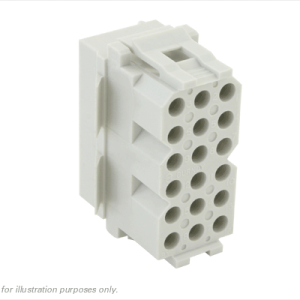

Connector, Interconnect, Quick Release Universal ZIF DIP Test & BURN-IN Socket, Socket

42-3572-11

Availability:

Available on backorder

CONN IC DIP SOCKET ZIF 42POS TIN

$33.680

Available on backorder

GENERAL SPECIFICATIONS

- STANDARD SOCKET BODY: (for -10, -10TL, -11, -16 sockets) black UL 94V-0 glass-filled

Polyphenylene Sulfide (PPS) - HIGH-TEMPERATURE SOCKET BODY: (for -18 socket) natural color Polyetheretherketone

(PEEK) - HANDLE: Stainless Steel

- HANDLE KNOB: Brass 360, 1/2-hard (no knob on loop handle)

- CONTACT MATERIAL: (for -10, -10TL, -11) BeCu 172 per QQ-C-553; (for -16)

Spinodal; (for -18) BeNi 360, 1/2-hard - BeCu CONTACT PLATING: 50µ [1.27µ] min. Ni under plate per QQ-N-290,

over plated with either: -10 200µ [5.08µ] min. matte Sn per ASTM

B545-97; or -10TL 200µ [5.08µ] min. 90/10 Sn/Pb per MIL-T-10727-11

10µ [0.25µ] min. Au per MIL-G-45204 - SPINODAL CONTACT PLATING: (for -16) 50µ [1.27µ] min. NiB

- HIGH-TEMPERATURE BeNi CONTACT PLATING: (for -18) 50µ [1.27µ]

NiB - CONTACT CURRENT RATING: 1 amp

- INSULATION RESISTANCE: 1000 MΩ min.

- DIELECTRIC WITHSTANDING VOLTAGE: 1000 VAC

- LIFE CYCLE: 25,000 to 50,000 cycles

- OPERATING TEMPERATURE: min. -85°F [-65°C]; max. 221°F [105°C]

for Sn plating, 302°F [150°C] for Au plating, 392°F [200°C] for

NiB plating, 482°F [250°C] for high-temperature socket - RETENTION FORCE (closed): 55 grams/pin based on a 0.020 [0.51] dia. test

lead - ACCEPTS LEADS: 0.015-0.035 [0.38-0.89] wide, 0.110-0.280 [2.79-7.11] long

FEATURES

- Universal ZIF DIP Test Socket accepts devices on 0.300 to 0.600 [7.62 to 15.24] centers

- All pin count sockets go into PCB with either 0.300 or 0.600 [7.62 to 15.24]

centers - Swing quick-release handle down to open contacts and insert device. Release

and handle automatically returns as contacts close onto device leads - Socket handle can be mounted on either the right or left side

- Sockets can be soldered into PCBs or plugged into any socket

Download: Datasheet

| Country Of Origin | US |

|---|

Brand

Aries Electronics

Corporate History

Aries Electronics, incorporated in 1972, began when the late William “Bill” Sinclair purchased the back panel line from Thomas & Betts Corporation. The line included IC sockets, headers, and printed circuit cards. Under Bill’s vision, Aries expanded the line to encompass a wide variety of packaging products, including sockets, headers and covers, programmable devices and a variety of jumper and cable assemblies. Aries has become established in the industry as a major source for unique connector products that solve a wide variety of packaging problems. Aries is the recognized industry leader in ZIF (Zero-Insertion-Force) Test Sockets for DIP, PGA, PLCC, and SOIC devices, and continues to be a leading source for a wide variety of specialty electronic connectors. In recent years, the company has made major inroads in the market for high-temperature sockets and flexible cable products. The addition of the Correct-A-Chip® product line established the company as a major source for “intelligent connectors” (incorporating other components, both passive and active), adapters (connectors that allow the use of one termination style on a board designed for a different termination style). Most recently, the company has developed and patented several concepts for BGA (ball grid array) and LGA (land grid array) sockets, and has acquired a high-frequency test and burn-in socket line, furthering growth in the test socket market.ARIES SUCCESS RESULTS FROM MASTERING SEVERAL MANUFACTURING PROCESSES…

- Custom High-Frequency (RF) Socket Design (-1dB Bandwidth at >60GHz)

- Patented Limited-Depth Pin Assembly (Correct-A-Chip Adaptors)

- Surface-mounting of Electronic Components onto adaptors

- Molding Engineered Plastics with Extremely Tight Tolerances (for devices on <0.2mm pitch)

- Bending Pins (Vertisocket™Line) LED/LCD applications

- Installation of Pins into Plastic

- Crimping Connectors on Flat Cable

- Flat Cable Wire Stripping and Separation